APV Plate Heat Exchanger Plates and Gaskets J092 Model for Chemical

Process and Industrial Applications

J092 Model Plate Heat Exchanger Operation & Configurations

Plate heat exchangers are one of the most versatile and

cost-effective methods for the heating and/or cooling of fluids.

The basic concept uses a corrugated heat transfer plate to separate

the hot fluid from the cold and transfer the heat between the

fluids.

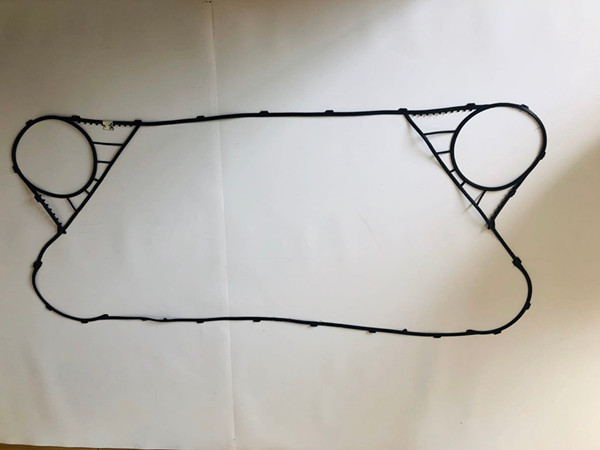

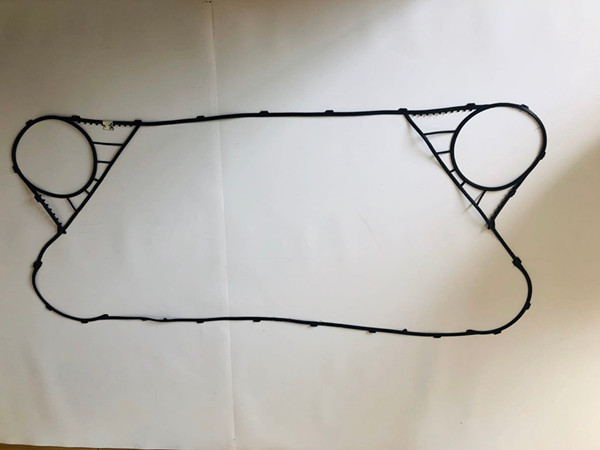

The seal between the plates is established by a peripheral gasket

which also separates the through ports and flow areas with a double

barrier. The gasket either allows the fluid to flow down the plate

channel or by-pass it to the adjacent plate channel as depicted in

Figure 1.

Plate heat exchangers can be used in a variety of different

configurations.

One configuration is closed circuit cooling, where the dirty

cooling medium such as sea, river, lake or tower water is isolated

at the plate heat exchanger and clean treated water is continually

recirculated through the process plant. This configuration, as

shown in Figure 2, protects process equipment from the dirty

cooling fluid.

J092 Model Plate Heat Exchanger Specification

| Surface Area | 0.92㎡ |

| Plate Theta Angle | 60 ° 120 ° |

| Connection Diameter | 229 mm |

| Plate Corrugate Thickness | 3.0 mm |

| Plate Centre Length* Width | 1290 * 465 mm |

| Plate Shape Length*Width | 1567 * 746 mm |

J092 Frame Dimensions

| FRAME | WIDTH inch | HEIGHT inch | H inch | NOMINAL CONNECTION SIZE inch | DESIGN PRESSURE |

| J060 M-10 | 34 7/8" | 61 7/8" | 13" | 8" | 150 psi |

| J092 M-10 | 34 7/8" | 76 5/8" | 13" | 8" | 150 psi |

| J107 M-10 | 34 7/8" | 84 1/16" | 13" | 8" | 150 psi |

| J154 M-10 | 33 7/16" | 103 1/8" | 13" | 8" | 150 psi |

| J185 M-10 | 34 7/8" | 121 7/8" | 13" | 8" | 150 psi |

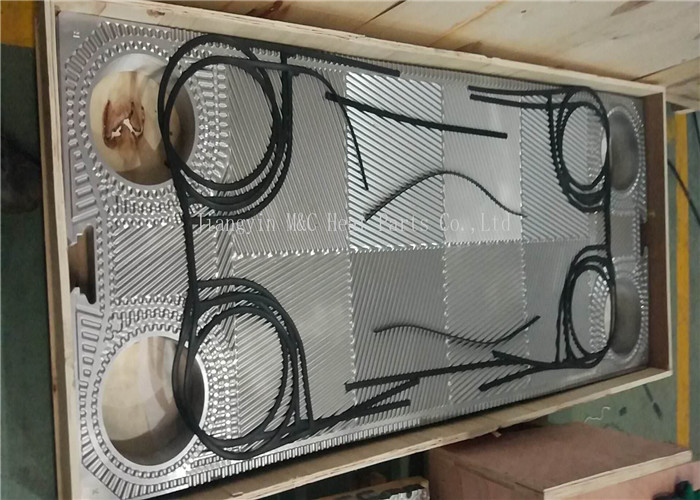

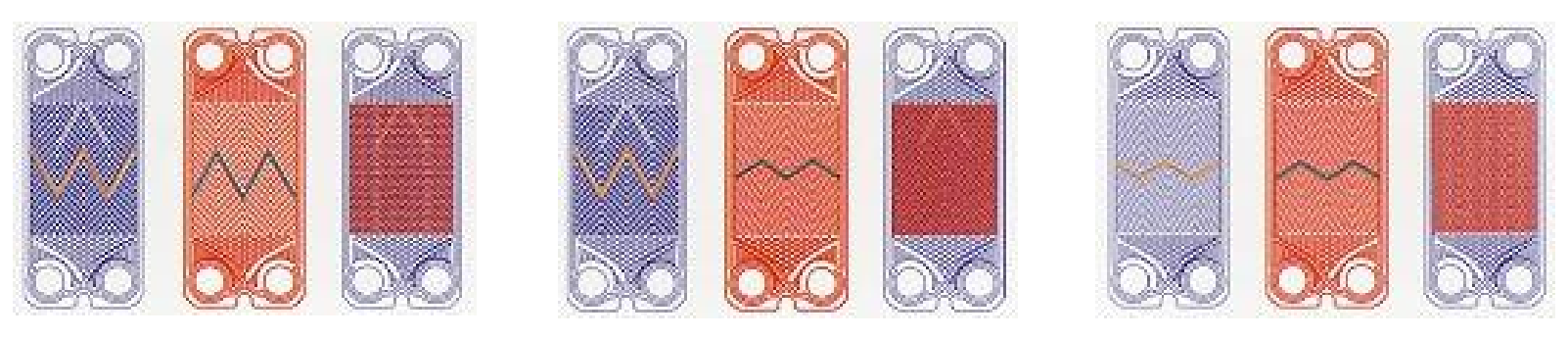

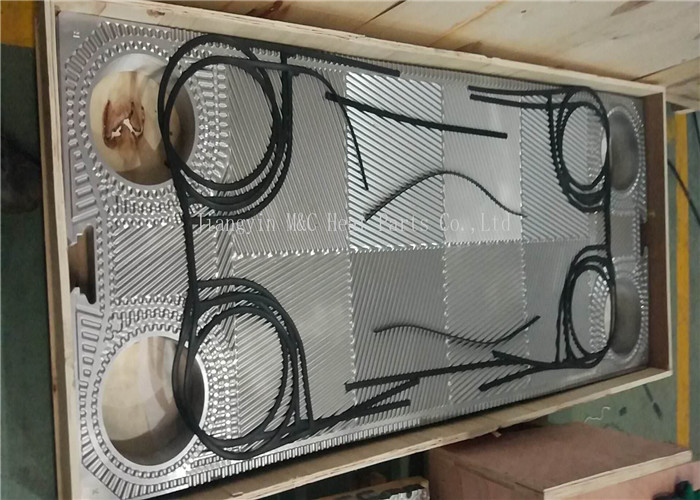

J092 Plate Heat Exchanger Gasket & Plate Picture

OEM & ODM PHE Gasket Parameters

Gaskets used in plate heat exchangers must have durability in

various liquid qualities and temperature / pressure conditions.

M&C has prepared the following gasket materials in order to

support a wide variety of applications.

| Material | Max Use Temperature | Hardness | Application Media |

| NBR | 120 ℃ | 76±2 | Alkane, alkane and other non-polar media, fuel oil and other

mineral oil; Lubricants; Animal and vegetable oils; Hot water,

saltwater, etc |

| NBR-HT | 140 ℃ | 76±2 |

| HNBR | 150 ℃ | 76±2 |

| EPDM | 150 ℃ | 80±2 | Water, steam, atmosphericozone, non-petroleum-based; Ketone;

Alcohols polar medium etc |

| HEPDM | 170 ℃ | 80±2 |

| Viton A | 180 ℃ | 80±2 | Acid, Alkali, Organic Solvent, Hot oil |

| Viton A(OIL) |

| Viton B |

| Viton G | 200 ℃ | 80±2 | Strong Acid, Hot oil saturated steam hot oil |

| CR | -40~60℃ | 75±2 | Refrigerant |

OEM & ODM PHE Plate Parameters

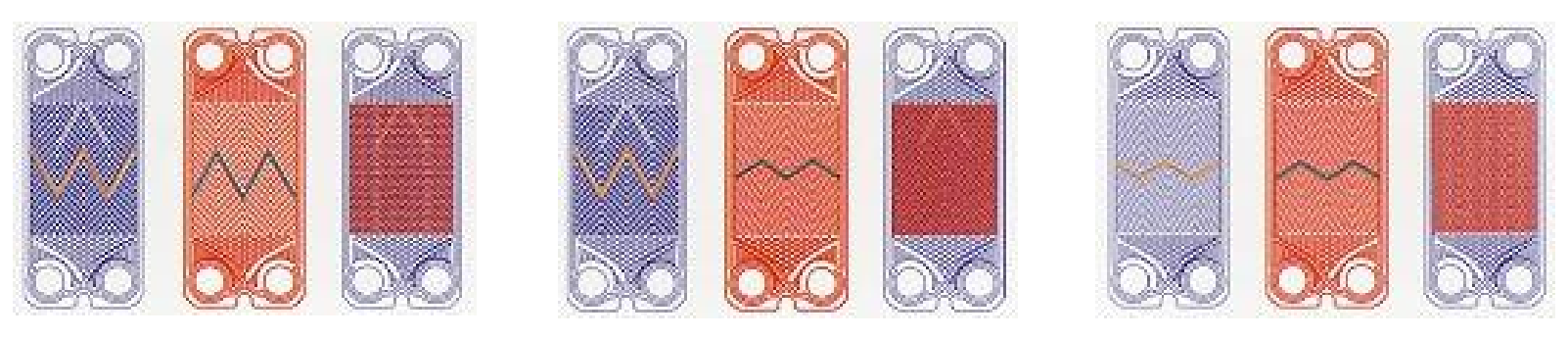

The plates are specially selected from various patterns so as to

achieve optimum area and cost effective heat exchanger for each

unit. These plates can be classified into three type, H type, L

type, Mix type.

Plate Corrugate

Low angle channel arrangement for lower allowable pressure drops

requirement applications;

Mixed channel arrangement for optional arrangement to gain the

optimized performance;

High angle channels arrangement for higher thermal performance and

allowable pressure drops requirement applications

The Standard Materials

304 Stainless Steel

This is the lowest cost heat transfer plate material. It has low

corrosion resistance and is usually only available in a thickness

of 0.5mm. This type of heat transfer plate is typically used in

HVAC applications.

316 Stainless Steel

This is the most common heat transfer plate material and is used in

many applications. 316 stainless steel has a high corrosion

resistance and is typically available in thickness from 0.5mm to

0.8mm.

Titanium

This type is very resistant to chemical attack, including most

acids, chloride, seawater and chlorine chemicals. This thickness of

titanium is usually from 0.5mm to 0.6mm.

Hastelloy C276

Other common names: Alloy C276, Hastelloy C, Inconel® C-276, Hastelloy C276.

Hastelloy C276 is a nickel-molybdenum-chromium superalloy with

tungsten added for excellent corrosion resistance in a variety of

harsh environments. Alloy C-276 is widely used in the harshest

environments such as chemical processing, pollution control, pulp

and paper production, industrial and municipal waste treatment, and

acid natural gas recovery. The thickness can range from 0.6mm to

0.8mm.

SMO 254

Sandvik 254 SMO is a high-alloy austenitic stainless steel

developed for use in seawater and other aggressive chloride-bearing

media. Thickness available from 0.6mm to 0.8mm.

PHE Plate Feature

| FEATURE | ADVANTAGES | WHAT'S IN IT FOR YOU! |

| A | DISTRIBUTION AREA | Efficient Flow Distribution | - Prevents Mal-Distribution

|

| B | CORRUGATED PLATE PATTERN-HEAT TRANSFER AREA | Promotes Turbulence, Minimize Fouling | - Excellent heat recovery effect

- Maximize run time

|

| C | PLATE LOCKING SYSTEMS | "Corner lock" and " bubble lock" concepts ensure a stable and well

aligned plate pack when the unit is closed | - Safe and economic operation

- High serviceability

- Minimum service downtime

|

| D | EASYCLIP GASKET SYSTEM | Bevelled gasket edges easily clip into place using your flingers Stays securely in place and provides high sealing integrity | - Reliable operation

- Easy and quick to replace

- No special tools needed

|

PHE Application Areas/Occasions

| Chemical | Coustic Soda, Fertilizer, Petrochemical, Oil Refinery, Oil & Fat,

Pharmaceutical, Sulfuric Acid Cooling |

| Food | Milk, Beer, Soft Drink, Sauce, Wine, Skid mounted Sterilizer |

| HVAC | Air-Conditioning, Top water heating |

| Steel Mill | Blast Furnace, Continuous Casting, C.O.G, Plating & Galvanizing,

Blast furmace cooling |

| Metal | Plating, Quenching, Anodizing, Painting |

| Pulp & Paper | Black Liquor, White Liquor, Digester, Heat Recovery |

| Textile | Synthetic Fiber, Spinning, Dyeing |

| Central Cooling | Sea Water, River Water, Power Station, Co-generation, Marine and

many others. |

J092 Plate Heat Exchanger Typical Chemcial Industry Applications

| Bauxite to alumina | Acrylic fibers | Gas/oil/water separation | Distillery pretreatment |

| Chlorine alkaline | Caprolactam (monomer for production of nylon 6) | Oil and gas production | Fermentation |

| Coke oven plant applications | Desulphurization | Polyester | Alcohol/ethanol |

| Soda ash | Ethylene glycol | Polystyrene | Pulp and paper |

| Steel plant applications | Ethylene oxide | PVC | Beet and cane sugar |

| Mining applications | Formaldehyde resins | Alkylation | Textiles |

| Sulphuric acid | Crude oil treatment | MTBE | Metal finishing |

| Titanium dioxide/pigments | Dehydration/desalting | Refinery | Automotive |

| Chloride process | Gas compression | Waste water treatment | |

| Zinc Phosphate | Gas treatment | Viscose (viscose rayon is regenerated cellulose) | |

J092 ADVANTAGES FOR CHEMICAL AND INDUSTRIAL APPLICATIONS

- Wide selection of gasket and plate materials to stand up to

aggressive process fluids

- Ease of cleaning and inspection

- Semi-welded pairs and gasketed plates available

- Semi-welded pairs reduce the chance of leakage

- Flexible configurations can be adapted to meet your changing

process needs

- Efficient operation

- High thermal efficiency saves money through reduction in required

heat transfer area

- Low liquid hold-up improves start-up time and reduces operating

fluid costs

- Acheves up to 97% heat recovery

- Eliminates complicated maintenance such as x-ray, ultrasonic and

other non-destructive test procedures

- Corrosion resistant materials reduce inspection and maintenance

while ensuring reliable operation

- No moving parts eliminates vibration and reduces maintenance

- Lower capital costs when compared to traditional sheel and tube

- Compact design saves space

- Life cycle cost reduction

- Reduced fouling leads to higher thermal efficiency, reducing

maintenance and operating costs

Plate Heat Exchanger Picture

M&C Heat Parts Company Profile

M&C Heat Parts Co., Ltd is founded in Wuxi, Jiangsu. M&C is

specialized in designing and manufacturing high quality heat

transfer equipment. The range of products comprises plates &

gaskets, plate heat exchangers, gasketed heat exchangers and brazed

heat exchangers. Thus, as one of the few producers worldwide,

M&C offers solutions with optimum thermodynamic designs for

different industries and virtually all applications.

M&C provide you with one-stop accessories service,

multuple-brand & multiple model alternatives for your choice. We'll

meet all your requirements of plate heat exchanger and keep your

machine running contunously through our rich storage and quick

response.

Moreover, we have a strict quality control and after-sales service

system, from material purchasing to finished product package until

the product received in good condition. Our products have been

widely used all over the world in various fields.

M&C Plate Heat Exchanger Plates & Gaskets Other Models

Recommend

Sondex/Danfoss - S4A, S7, S20, S21, S22, S41, S43, S47, S65, S81,

S86, S100, S120, S130, SFD7, SFD13, SW19 and so on;

APV/SPX - H17, N25, N35, A055, A085, J060, J092, J107, M92, M107,

K55, K71, B110, B134, P105, P190, SR1, SR2, TR9GN, TR9AL and so on;

Tranter/Swep - GX12, GL13, GC26, GC51, GX26, GX51, GX42, GX64,

GX85, GX91, GX140, GX145 and so on;

API/Schmidt - Sigma 7, Sigma 9, Sigma 13, Sigma 26, Sigma 27, Sigma

36, Sigma 66, Sigma 106, Sigma 229, Sigma Star 45, Sigma Star 90

and so on;

Vicarb - V4, V13, V20, V28, V45, V60, V100, V110, V130 and so on;

Hisaka - EX11, EX15, EX15, LX026, LX195, LX395, LX595, RX135,

RX395, RX595, UX115, UX225, UX395, UX495, UX815, UX995 and so on;

GEA - VT04, VT10, VT20, VT40, VT80, VT405, VT805, VT1306, NT50M,

NT50X, NT100S, NT150S, NT150L, NT250M, NT250L and so on;

Funke - FP04, FP05, FP14, FP16, FP08, FP22, FP31, FP40, FP41, FP70,

FP100, FP120 and so on;

Thermowave - TL200SS/PP, TL250SS/PP, TL400SS/PP. TL650SS/PP and so

on;

DHP - DX143, DX146, DX20V, DX20DL, DX20DM, DX30S, DX36M and so on;

LHE - HT101, HT102, HT104, HT151, HT152, HT202, HT232, HT233 and so

on;

M&C Plate Heat Exchanger Goods ready to Delivery