Seawater Heat Exchanger Sondex S100 Plate Heat Exchanger Gasket and

Plate for Marine Oil Cooler

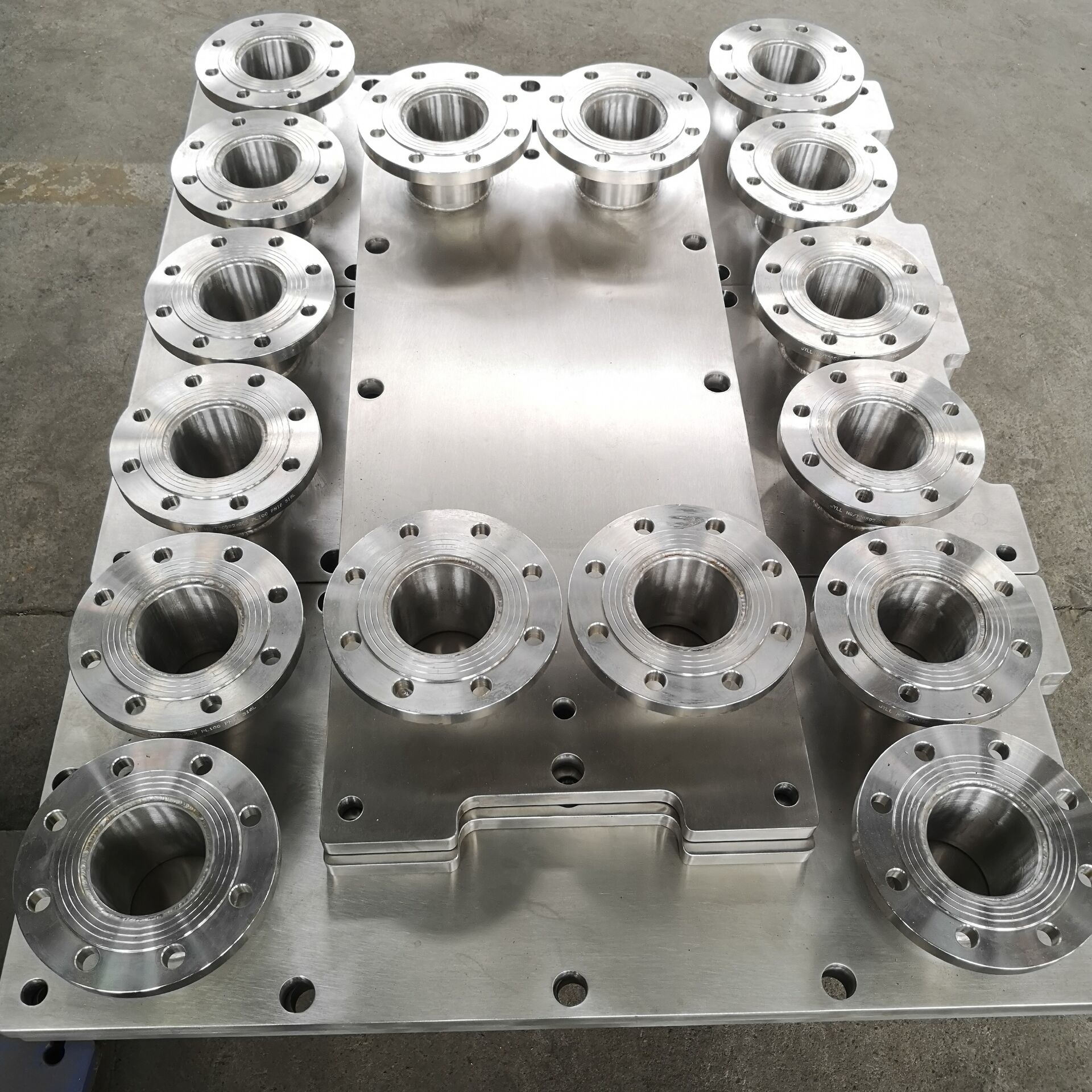

S100 Plate Heat Exchanger Construction

| Frame | Plates | Gaskets |

- The heat exchanger consists of a frame plate(head), a pressure

plate(follower), a carrying bar, a lower bar and a column.

Tie(clamping) bolts are used to press the plate package together.

The size and number is depending on the type of heat exchanger.

| - The plate package consists of plates with a groove along the rim of

the plate and around the ports. The number of plates is, as well as

size and dimension, dependant on the thermal output required.

Depending on the application stainless steel or titanium plates

might be used

| - The groove provided in the plates holds the special gasket. The

purpose of this gasket is to prevent intermixing of the media and

leakage to the outside. The gaskets are selected to suit the actual

combination of temperature, chemical resistance and possible other

conditions to be considered. They can be supplied in Viton, Nitrile

or EPDM.

|

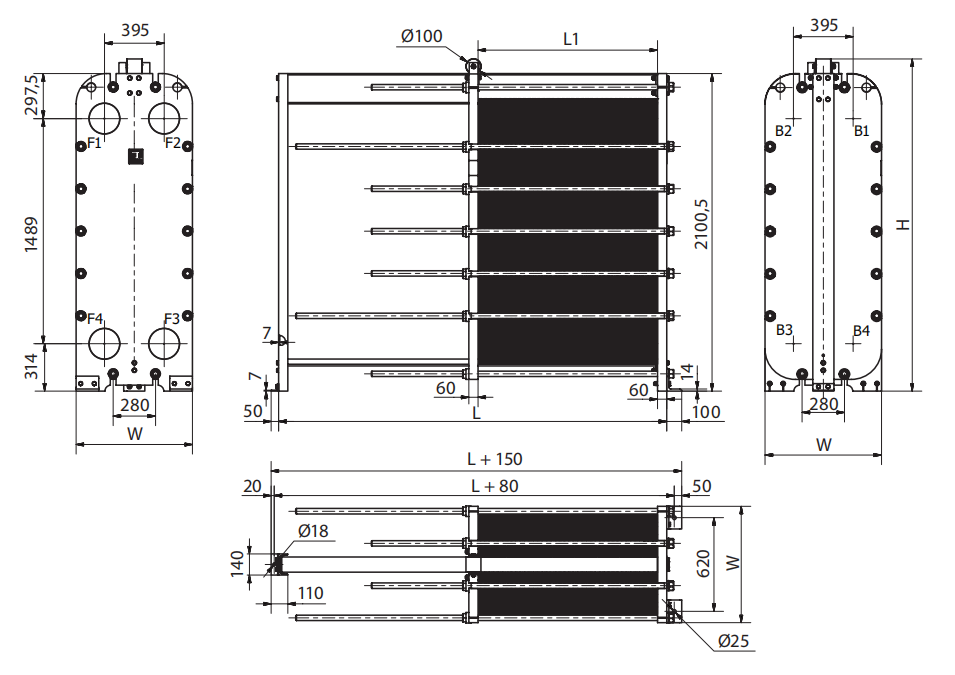

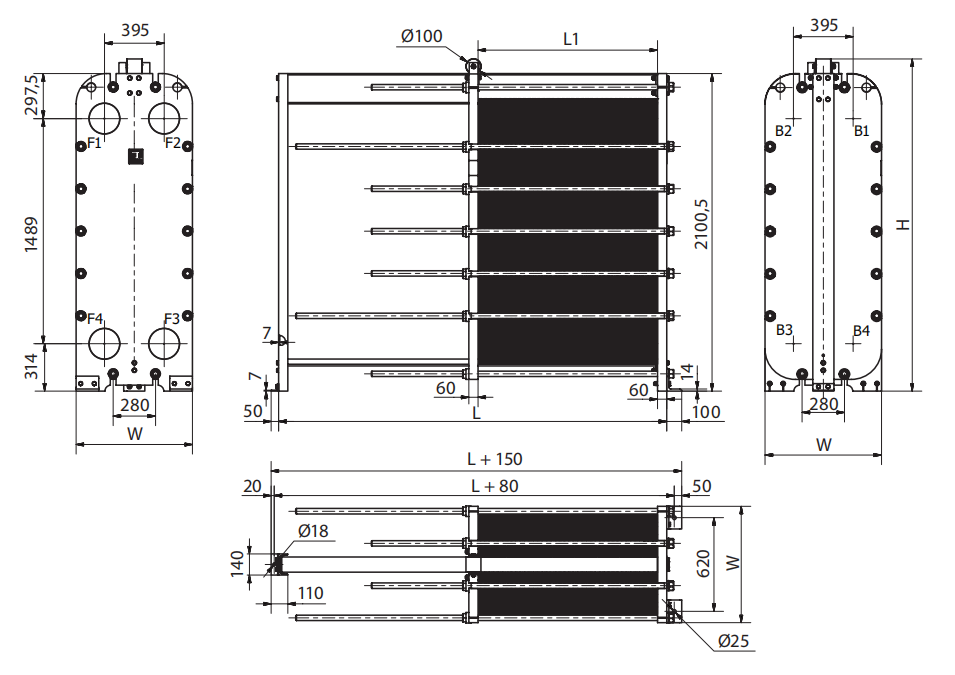

S100 Model Plate Heat Exchanger Specification

| Surface Area | 1.0㎡ |

| Plate Theta Angle | 61 ° 121 ° |

| Connection Diameter | 202 mm |

| Plate Corrugate Thickness | 2.6 mm |

| Plate Centre Length* Width | 1489 * 395 mm |

| Plate Shape Length*Width | 1756 * 656 mm |

| Gasket Type | Sonderlock type and Glue Type |

S100 Plate Heat Exchanger Technical Information

| Frame | - Painted frame

- Stainless steel frame, designed for the food and daily industry

- Both frames comes with clamping bolts placed around the frame edge.

|

| Design Pressure | - Painted frames: 1.0/1.5/2.5 Mpa. (145/217/362 PSI)

- Stainless steel frame: 1.0/1.6 Mpa (145/232 PSI)

|

| Intermediate Frames | - Intermediate frames and corner blocks in stainless steel.

|

| Connections | - DN150/6" flange in carbon steel, rubberlined or cladded with AISI

316 or titanium

- DN100/4", DN125/5" and DN150/6" dairy unions

- According to all known standards.

|

| Plate Material | - AISI304/316, 254 SMO and titanium.

- Other materials available on request.

|

| Gaskets | - The gasket is placed in the closed gasket groove, that is formed by

the plates. This design makes the plate suitable for high working

pressures. The plates are strongly guided during the assembly of

the plate heat exchanger. Materials: NBR, EPDM and Viton.

- Other materials available on request.

|

| Extra Equipment | - Safety cover in stainless steel

- Insulating jacket

- Assembling spanner

- Foundation feet for common frame

- Instrument flange

- Thermometer and manometer

|

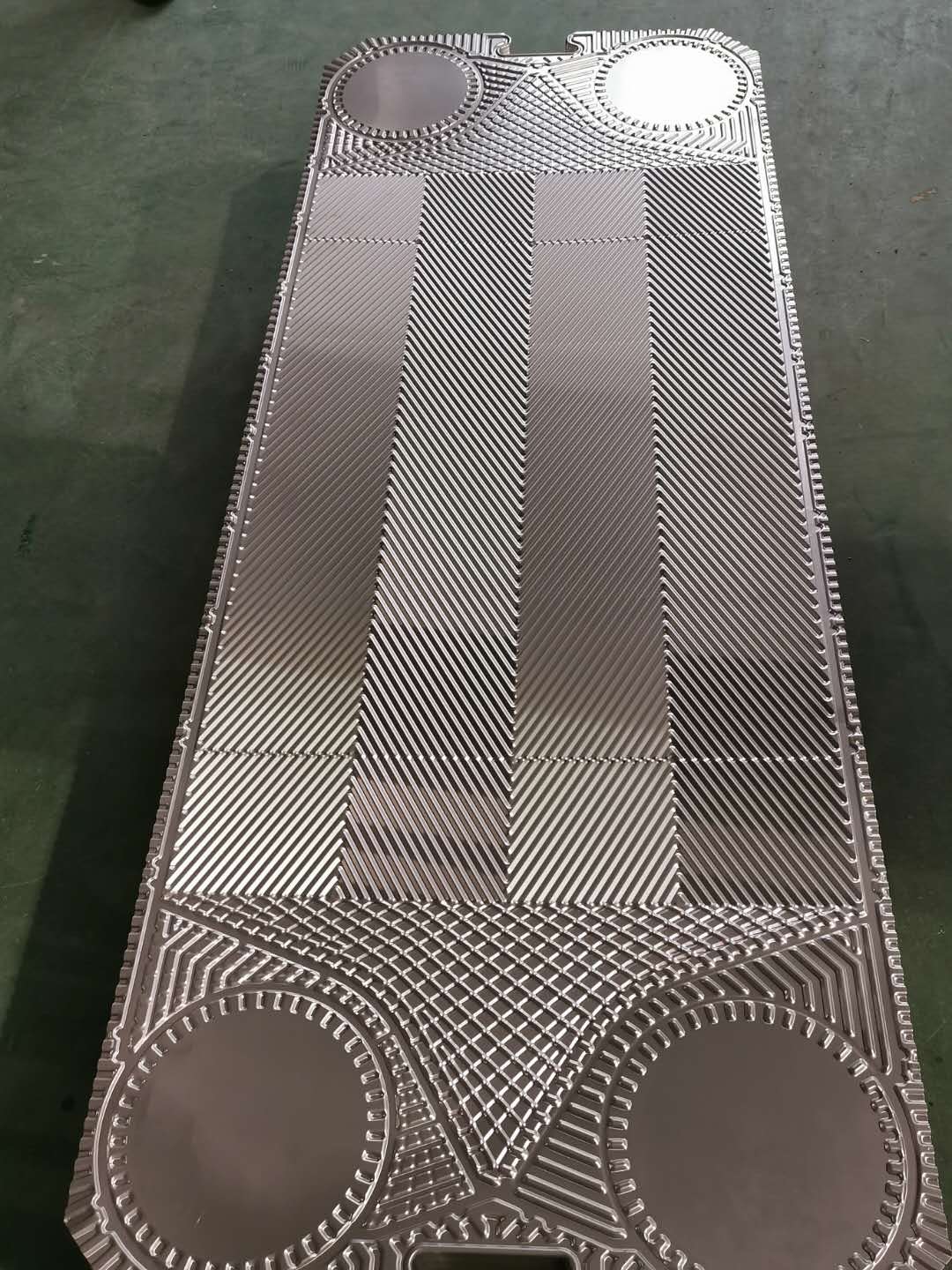

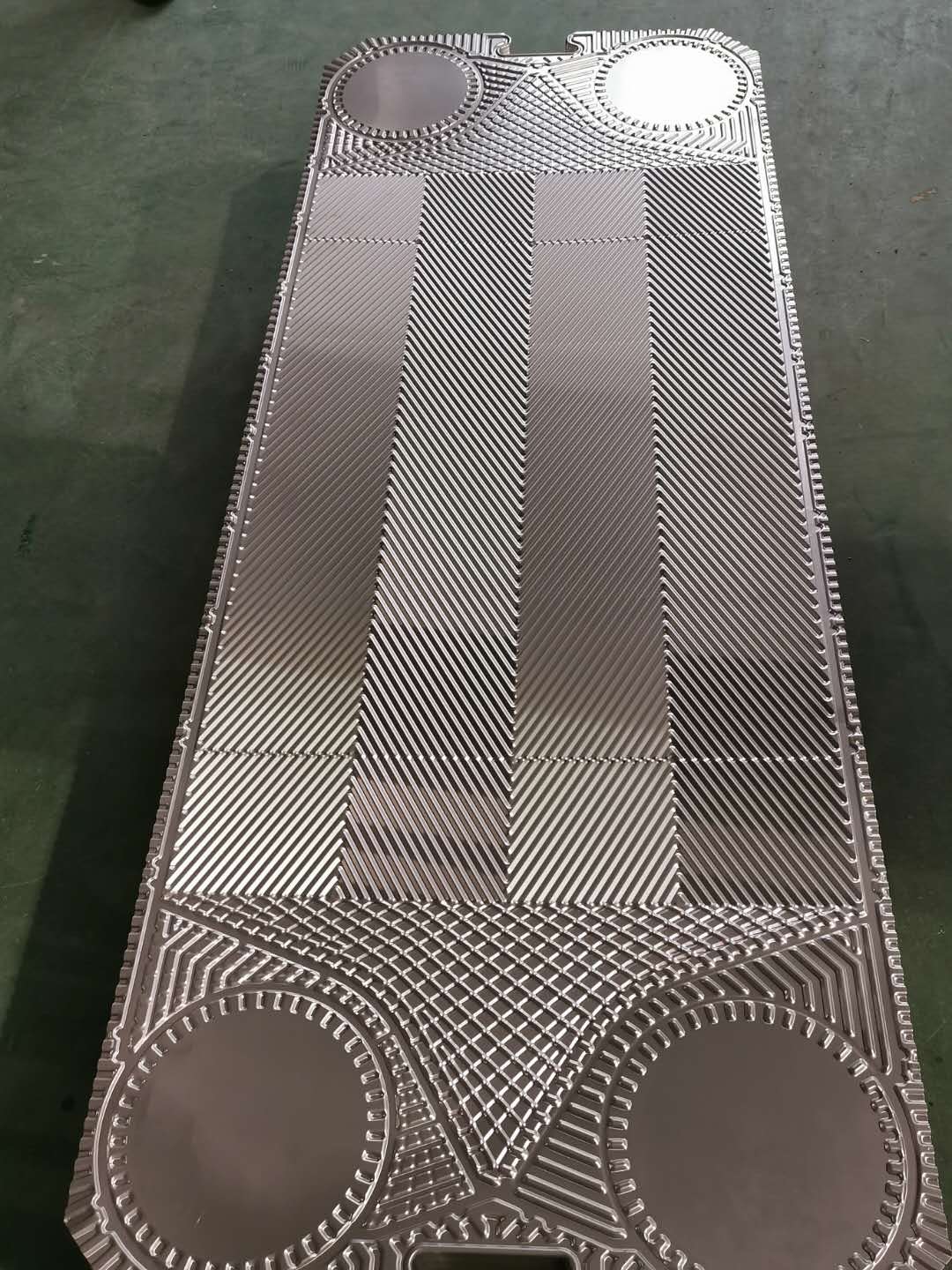

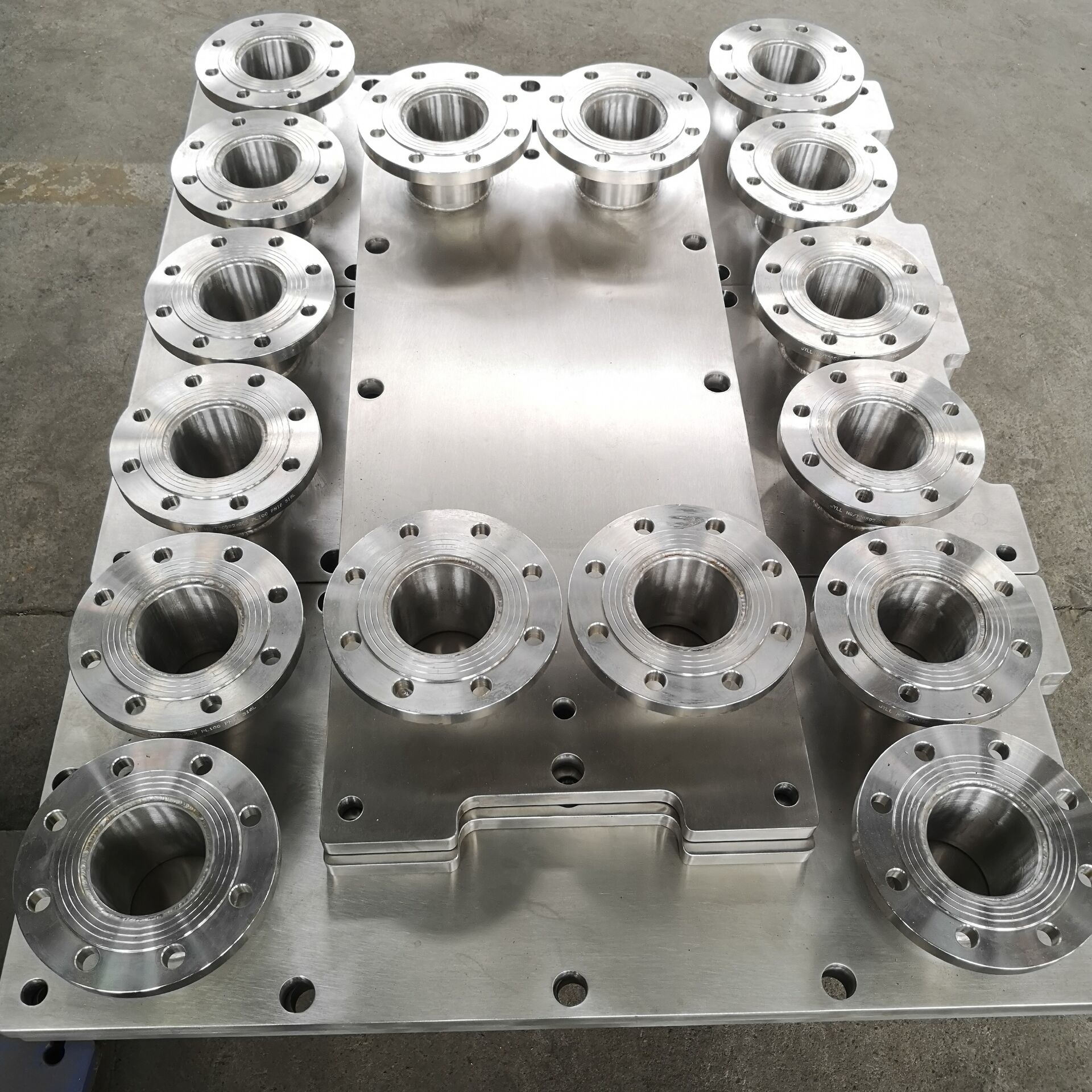

S100 Plate Heat Exchanger Gasket & Plate Pictures

S100 Frames

| Number of Plates | L(frame length)(mm) | W(mm) | H(mm) | Weigth max,empty(kg) | Connection type |

| S100 IS16 |

| 7-64 | 667 | 770(30.31") | 2198(86.53") | 1805 | DN 200 flange or 8" |

| 65-137 | 1067 | 2194 |

| 138-191 | 1367 | 2489 |

| 192-228 | 1567 | 2689 |

| 229-319 | 2067 | 3188 |

| 320-410 | 2567 | 3692 |

| 411-500 | 3067 | 4193 |

| 501-682 | 4067 | 5204 |

| 683-864 | 5210 | 790(31.10”) | 2505.5(98.64") | 6214 |

| 865-1046 | 6210 | 7267 |

| S100 IS25 |

| 7-61 | 677 | 790(31.10") | 2200.5(86.63") | 2019 | DN 200 flange or 8" |

| 62-133 | 1077 | 2505 |

| 134-186 | 1377 | 2864 |

| 187-222 | 1577 | 3108 |

| 223-311 | 2077 | 3710 |

| 312-400 | 2577 | 4312 |

| 401-490 | 3077 | 4921 |

| 491-668 | 4077 | 6125 |

| 669-847 | 5220 | 790(31.10") | 2505.5(98.64") | 7686 |

| 848-1025 | 6220 | 8944 |

PHE Plate Feature

| FEATURE | ADVANTAGES | WHAT'S IN IT FOR YOU! |

| A | DISTRIBUTION AREA | Efficient Flow Distribution | - Prevents Mal-Distribution

|

| B | CORRUGATED PLATE PATTERN-HEAT TRANSFER AREA | Promotes Turbulence, Minimize Fouling | - Excellent heat recovery effect

- Maximize run time

|

| C | PLATE LOCKING SYSTEMS | "Corner lock" and " bubble lock" concepts ensure a stable and well

aligned plate pack when the unit is closed | - Safe and economic operation

- High serviceability

- Minimum service downtime

|

| D | EASYCLIP GASKET SYSTEM | Bevelled gasket edges easily clip into place using your flingers Stays securely in place and provides high sealing integrity | - Reliable operation

- Easy and quick to replace

- No special tools needed

|

PHE Gasket Type

Please check their are three common model gasket type are aways

used in Sondex brand.

S100 Plate Heat Exchanger in Marine Cooling System

Most Cooling systems are made as central cooling systems, which

means that there is only one or two bigger plate heat exchangers

equipped with titanium plates.

Titanium is the only material that can withstand the aggressive

seawater without corrosion damages on the plates in the heat

exchanger. This means that the central cooler can operate without

problems using seawater as the cooling media for the internal

freshwater cooling system.

The advantage of a central cooler is that the use of the corrosive

seawater is limited to one or two plate heat exchangers, and

thereby the use of exotic material for the plate heat exchanger and

the seawater pipeline is limted to a minimum, which will reduce the

corrosion damage in the cooling system.

The rest of the plate heat exchangers is normally equipped with

stainless steel plates there is no corrosion risk as the heat

exchangers work with freshwater.

| 1. Main Engine | 2.Auxiliary Engine | 3. Heat exchanger for Central Heating | 4. Freshwater Generator |

| 5. Central Cooler | 6. Gear Oil Cooler | 7. Lubricating Oil Cooler, Auxiliary Engine | 8. Lubricating Oil Cooler, Main Engine |

| 9. Seawater Filter | 10. Seawater Pump | 11. Freshwater Pump | |

PHE Problem Solving

If you have problems with your plate type heat exchanger, in most

cases these can be solved by your own personnel. Please find below

a summary of possible problems as well as possible causes and

solutions.

A condition for the continuous proper functioning of your plate

type heat exchanger is in strict compliance with the permissible

values for pressure and temperature mentioned on the name plate.

Exceeding these values, even as a short-lasting pressure peaks will

cause damage to the unit and be the cause of problems.

To avoid costly repairs, we advise you to have the installation

work and maintenance carried out by properly trained personnel. You

can also contact us.

| Problem | Possible Cause | Possible Solution |

| Leakage | At the connections | - Check the rubber liners (if fitted)

- Check the flange gasket(if fitted)

- Check the O-ring

- Fit the pipes tension-free

|

| Mixing of primary and secondary circuit | - Check the plates for holes and/or cracks

|

| In plate package | - Check the assembly

- Check the condition of the gaskets

- Check the proper position of the gasket

|

| The operating Conditions deviate from the specification | - Adjust the operating conditions

|

| Insufficient Capacity | Air in the system | - De-aerate the pipe system

- Check the pipe work for possible air traps

|

| The operating conditions deviate from the specification | - Adjust the operating conditions

|

| The heat exchanger is dirty | |

| The connections have been interchanged | |

| Too high pressure drop | Flow large the design flow | |

| Channels in plate(s) blocked | |

| Incorrect measurements | - Check the pressure indicator

|

| Medium deviating from the design | - Addition of for instance anti-freeze will increase the pressure

drop

|

| Air in the system | - De-aerate the pipe system

- Check the pipe work for possible air traps

|

Plate Heat Exchanger Pictures

M&C Heat Parts Company Profile

M&C Heat Parts Co., Ltd is founded in Wuxi, Jiangsu. M&C is

specialized in designing and manufacturing high quality heat

transfer equipment. The range of products comprises plates &

gaskets, plate heat exchangers, gasketed heat exchangers and brazed

heat exchangers. Thus, as one of the few producers worldwide,

M&C offers solutions with optimum thermodynamic designs for

different industries and virtually all applications.

M&C provide you with one-stop accessories service,

multuple-brand & multiple model alternatives for your choice. We'll

meet all your requirements of plate heat exchanger and keep your

machine running contunously through our rich storage and quick

response.

Moreover, we have a strict quality control and after-sales service

system, from material purchasing to finished product package until

the product received in good condition. Our products have been

widely used all over the world in various fields.

M&C Plate Heat Exchanger Plates & Gaskets Other Models

Recommend

Sondex/Danfoss - S4A, S7, S20, S21, S22, S41, S43, S47, S65, S81,

S86, S100, S120, S130, SFD7, SFD13, SW19 and so on;

APV/SPX - H17, N25, N35, A055, A085, J060, J092, J107, M92, M107,

K55, K71, B110, B134, P105, P190, SR1, SR2, TR9GN, TR9AL and so on;

Tranter/Swep - GX12, GL13, GC26, GC51, GX26, GX51, GX42, GX64,

GX85, GX91, GX140, GX145 and so on;

API/Schmidt - Sigma 7, Sigma 9, Sigma 13, Sigma 26, Sigma 27, Sigma

36, Sigma 66, Sigma 106, Sigma 229, Sigma Star 45, Sigma Star 90

and so on;

Vicarb - V4, V13, V20, V28, V45, V60, V100, V110, V130 and so on;

Hisaka - EX11, EX15, EX15, LX026, LX195, LX395, LX595, RX135,

RX395, RX595, UX115, UX225, UX395, UX495, UX815, UX995 and so on;

GEA - VT04, VT10, VT20, VT40, VT80, VT405, VT805, VT1306, NT50M,

NT50X, NT100S, NT150S, NT150L, NT250M, NT250L and so on;

Funke - FP04, FP05, FP14, FP16, FP08, FP22, FP31, FP40, FP41, FP70,

FP100, FP120 and so on;

Thermowave - TL200SS/PP, TL250SS/PP, TL400SS/PP. TL650SS/PP and so

on;

DHP - DX143, DX146, DX20V, DX20DL, DX20DM, DX30S, DX36M and so on;

LHE - HT101, HT102, HT104, HT151, HT152, HT202, HT232, HT233 and so

on;

M&C Plate Heat Exchanger Goods ready to Delivery