Varitherm GEA Plate Heat Exchangers VT20/VT20P/VT20M OEM PHE Plates

and Gaskets In Food Industry

VT20/VT20P/VT20M Plate Heat Exchanger Construction

With Safetytherm, experts have succeeded in designing an extremely

reliable version of a conventional sealed plate heat exchanger. Two

extremely thin plates with welded inlet and outlet openings form a

small leakage gap within a double-wall plate. In the seldom event

of a plate crack occurring, this clever solution with special

leakage channels ensures that a mixture of a non-compatible media

is excluded and the leakage is visible.

The compact design and function of Safetytherm meets the high

standards. Our customers can be certain of one thing: Safetytherm

is a shining example of an effective and low-maintenance

double-plate solution which guarantees a high level of production

safety.

VT20 Model Plate Heat Exchanger Specification

| Surface Area | 0.26㎡ |

| Plate Theta Angle | 127 ° 127 ° |

| Connection Diameter | 79 mm |

| Plate Corrugate Thickness | 3.9 mm |

| Plate Centre Length* Width | 868 * 212 mm |

| Plate Shape Length*Width | 999 * 337 mm |

VT20/VT20P/VT20M Plate Heat Exchanger Technical Information

| Model | Connection Size | Dim.A | Dim.B | Dim.C |

| VT20 Safetytherm | 3"(DN80) | 21.4"(620mm) | 56.6"(1488mm) | Up to 127"(3235mm) |

| VT40 Safetytherm | 5"(DN125) | 28.0"(710mm) | 74.2"(1885mm) | Up to 139"(3535mm) |

Heat Transfer Plate: 316L Stainless Steel.

Gasket: NBR, EPDM, Viton, and others on request.

Port Connection: Unlined, Metal Lined, Raised Welded Neck Flange and others on

request.

Maximum Design Pressure: 230 psig(16 barg)

Maximum Design Temperature: 370 ° F(190 °C), depending on gasket selection

Approximate Maximum Liquid Flow Rate: VT20 Saftetytherm:440 gpm (100m³/hour)

VT40 Saftetytherm: 924 gpm (210m³/hour)

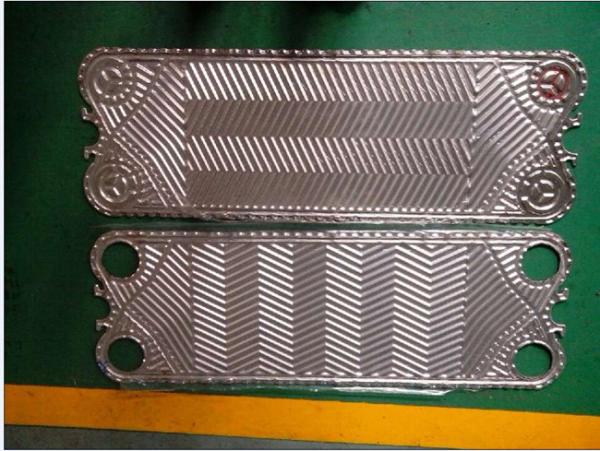

VT20/VT20P/VT20M Plate Heat Exchanger Gasket & Plate Pictures

VT20/VT20P/VT20M Gasketed Plate Heat Exchanger - Varitherm Systematic Product

Variety

Whether in heating or cooling of liquids containing particles of up

to 2mm in size, in condensing vapours or in gas cooling and gas

dehumidifying in special cases- Varitherm plate heat exchangers

offer a convincing solution with the widest range of possible

applications.

The Varitherm Series has two convincing arguments in its favour.

Firstly there is a wide range of materials available, including

1.40301/AISI304, nickel-based alloy, Incolloy, nickel, tantalum and

titanium. Secondly it comes with an individual plate pack that can

be easily expanded to meet your future needs. And this makes the

Varitherm Series the optimum economic solution for just about every

application.

Advantages at a Glance |

- Operating pressure up to 25 bars, test pressure up to 32.5 bars

| - Plates in various sizes, corrugations and materials

| - Adhesive-free LocIn gasket system for model sizes VT20-VT80

|

- NBR, EPDM and FPM gasket materials

| - Special gasket materials, such as silicone, Hypalon and butyl

available on request

| - Lacquered frames for all model sizes

|

- Stainless steel frames for model sizes VT04 to VT80

| | |

| Benefits at a Glance | - High level of production safety

- Effective heat transfer

- Compact design

- Low leakage risk

- Easy maintenance

|

Gentle product handling

The gentle treatment of products caused by the soft corrugation

makes the Varitherm the obvious choice for the foodstuffs industry.

PHE Type of Safetherm and Varitherm

| Safetytherm | VT10 VT20 VT40 |

| Varitherm | VT04 VT10 VT20 VT40 VT80 VT130 VT180 VT250 VT405 VT805 VT1306 VT2508 |

VT20/VT20P/VT20M Frame

PHEs are available in various application-specific frame versions.

The basic versions are the C and B designs, with the B design being

used above all for longer plate packs.Variants of these designs are

marked by further abbreviations.

Special Stianless steel versions are employed in foodstuff and

pharmaceutical applications and may include intermediate plates for

separating the individual sections.

Some frames are equipped with height-adjustable bases

PHE Troubleshooting

1. Insufficient Performance

| Fault | Cause | Remedy |

| Reduced heat transfer | Deposits on the HE plates | Clean HE plates - Cleaning HE plates while PHE is open and cleaning

HE plates while PHE is closed. |

| Operation, flow media etc. differing from the design case | Have PHE design with new operating data checked by M&C |

| Excessive pressure loss | Plugging of manifold flow gaps obstructs flow | Clean HE plates - Cleaning HE plates while PHE is open and cleaning

HE plates while PHE is closed. |

| Incorrect installation of HE plates obstructs flow | Check installation order by means of circuit diagram |

| Operation, flow media etc.differing from the design case | Have PHE design with new operating data checked by M&C |

2. Leaks

| Fault | Cause | Remedy |

| Leaks between the HE plates - flow media escape from the HE plate

pack | Incorrect tensioning dimension of PHE | Check correct tensioning dimension according to rating plate data |

| Excessive operating pressure | Check operating pressure according to rating plate data |

| Operating temperatures too high/too low | Check operating temperatures according to rating plate data |

| HE plate gaskets are not properly seated | Open the PHE and correct the seat of HE plate gaskets |

| HE plate gaskets are soiled | Open the PHE and clean the HE plate gaskets |

| HE plate gaskets either defective or hardened | Open the PHE and replace the HE plate gaskets |

| Leaks between HE plates and frames, reinforcement plates and

intermediate plates | Incorrectly seated HE plate and frame gaskets | Open the PHE and correct seat of plate and frame gaskets |

| HE plate and frame gaskets are soiled | Open the PHE and clean the HE plate and frame gaskets |

| HE plate and frame gaskets are defective | Open the PHE and replace the HE plate and frame gaskets |

| Leaks between frame connection and pipework | Excessive load of frame connection from pipework | Reduce connecting loads to permitted values |

| Gasket improperly seated | Slacken off frame connection and correct gasket seat |

| Dirty gasket | Slacken off frame connection and clean the gasket |

| Defective gasket | Slacken off frame connection and replace the gasket |

| Flange connection is not sufficiently tightened | Check gasket and retighten connection evenly if required |

| Damaged HE plates | Excessive tightening of HE plate pack (tensioning dimension below a

min.) | Replace defective HE plates |

| Damaged HE plates | Corrosion of HE plate material | Check design of PHE regarding flow media, contact M&C |

| Damaged HE plates at the beginning or at the end of the PHE | Incorrect earthing when welding on special connections to open

frame connecting pipes | Repalce defective HE plates |

Plate Heat Exchanger Pictures

M&C Heat Parts Company Profile

M&C Heat Parts Co., Ltd is founded in Wuxi, Jiangsu. M&C is

specialized in designing and manufacturing high quality heat

transfer equipment. The range of products comprises plates &

gaskets, plate heat exchangers, gasketed heat exchangers and brazed

heat exchangers. Thus, as one of the few producers worldwide,

M&C offers solutions with optimum thermodynamic designs for

different industries and virtually all applications.

M&C provide you with one-stop accessories service,

multuple-brand & multiple model alternatives for your choice. We'll

meet all your requirements of plate heat exchanger and keep your

machine running contunously through our rich storage and quick

response.

Moreover, we have a strict quality control and after-sales service

system, from material purchasing to finished product package until

the product received in good condition. Our products have been

widely used all over the world in various fields.

M&C Plate Heat Exchanger Plates & Gaskets Other Models

Recommend

Sondex/Danfoss - S4A, S7, S20, S21, S22, S41, S43, S47, S65, S81,

S86, S100, S120, S130, SFD7, SFD13, SW19 and so on;

APV/SPX - H17, N25, N35, A055, A085, J060, J092, J107, M92, M107,

K55, K71, B110, B134, P105, P190, SR1, SR2, TR9GN, TR9AL and so on;

Tranter/Swep - GX12, GL13, GC26, GC51, GX26, GX51, GX42, GX64,

GX85, GX91, GX140, GX145 and so on;

API/Schmidt - Sigma 7, Sigma 9, Sigma 13, Sigma 26, Sigma 27, Sigma

36, Sigma 66, Sigma 106, Sigma 229, Sigma Star 45, Sigma Star 90

and so on;

Vicarb - V4, V13, V20, V28, V45, V60, V100, V110, V130 and so on;

Hisaka - EX11, EX15, EX15, LX026, LX195, LX395, LX595, RX135,

RX395, RX595, UX115, UX225, UX395, UX495, UX815, UX995 and so on;

GEA - VT04, VT10, VT20, VT40, VT80, VT405, VT805, VT1306, NT50M,

NT50X, NT100S, NT150S, NT150L, NT250M, NT250L and so on;

Funke - FP04, FP05, FP14, FP16, FP08, FP22, FP31, FP40, FP41, FP70,

FP100, FP120 and so on;

Thermowave - TL200SS/PP, TL250SS/PP, TL400SS/PP. TL650SS/PP and so

on;

DHP - DX143, DX146, DX20V, DX20DL, DX20DM, DX30S, DX36M and so on;

LHE - HT101, HT102, HT104, HT151, HT152, HT202, HT232, HT233 and so

on;

M&C Plate Heat Exchanger Goods ready to Delivery