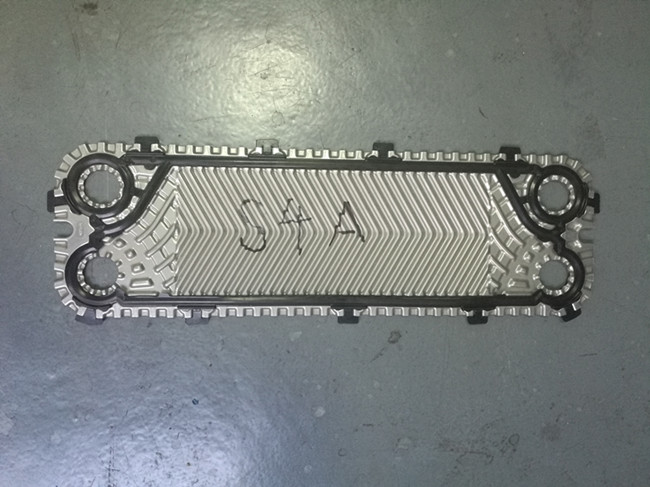

DN32 Connection Sizes S4/S4A Sondex Plate Heat Exchanger with

Stainless Steel AISI 304 Material Frame For Milk /Beer Company

S4/S4A Plate Heat Exchanger Construction

The type S4A and S8A plate range with lengths up to 0.75m (2.5 ft)

and a "long" thermal pattern will cover many duties up to 6 m³/h

(26 gpm) in a single pass solution, meaning that all the

connections are on the head side, This will ensure easy pipe- and

service work, and by dismantling the exchanger for service, no

pipes need to be removed.

This plate range is designed for a small-sized pasteurization up to

3.000 l/h (depending on the type of product and the temperture

profile) and ensures a gentle and soft product treatment.

The heat transfer is obtained, when the warm medium transfers

energy through the thin, strong flow plates between the channels

and delivers it to the cold opposing medium without mixing the two

media. Counter-current flow creats the optimal efficiency. The

plate- and inlet design allows effective,easy CIP (Cleaning in

Place) of all "flow" surfaces.

S4/S4A Model Plate Heat Exchanger Specification

| Surface Area | 0.04㎡ |

| Plate Theta Angle | Horizontal 130° Horizontal 130° |

| Connection Diameter | 28mm |

| Plate Corrugate Thickness | 2.35 mm |

| Plate Centre Length* Width | 381*70 mm |

| Plate Shape Length*Width | 449*140 mm |

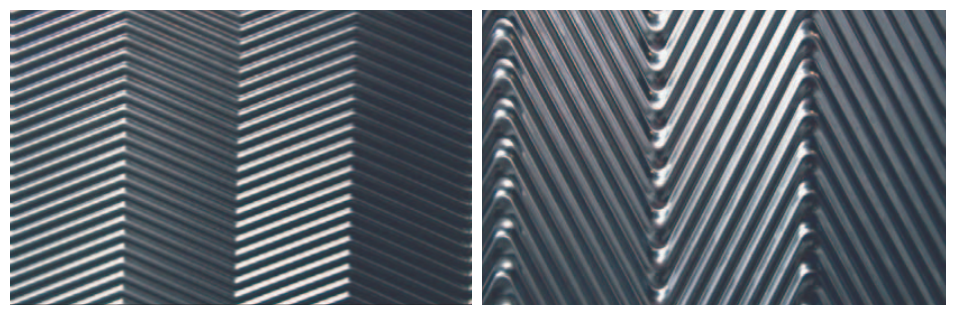

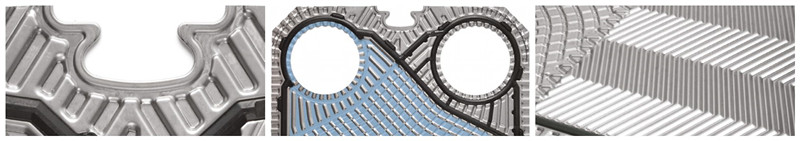

S4/S4A Plate Heat Exchanger Gasket & Plate Pictures

S4/S4A Frames

| Number of Plates | L(frame length)(mm) | W(mm) | H(mm) | Weigth max,empty(kg) | Connection type |

| S4A IG16 |

| 7-34 | 270 | 200(7.87") | 473(18.62") | 44 | 1.25" threaded pipe 1" Dairy Union |

| 35-45 | 320 | 47 |

| 46-68 | 420 | 56 |

| 69-90 | 520 | 63 |

| S4A IS16 |

| 7-21 | 434 | 200(7.87") | 621(24.45") | 46 | 1.25" threaded pipe 1" Dairy Union |

| 22-32 | 634 | 49 |

| 33-55 | 1034 | 58 |

| 56-78 | 1334 | 65 |

S4/S4A Plate Heat Exchanger Technical Data

| Type | S1 | S4A | S6A | S8A |

| Max. working pressure | PN (bar) | 10.16 |

| Max. operating temperature | °C | Up to 180 |

| Min. operating temperature | -10 |

| Flow medium | Water and different fluids, steam |

| Volume/channel | I | 0.09 | 0.17 | 0.13 | 0.21 |

| Connection size | DN32/1.25" |

| Connection type | - 1.25" pipe or threaded pipe in stainless steel or titanium(other

materials available on request)

- DN 25/1" Dairy union (for food/sanitary industry frames only)

|

| Plate material | - Stainless steel EN 1.4404(AISI 316L), EN 1.4301(AISI 304), SMO254,

Hastelloy C276, titanium GR.1

- Other materials available on request

|

| Plate thickness | mm | - 0.5

- Other materials available on request

|

| Gasket material | - NBR, EPDM, FKM

- Other materials available on request

|

| Gasket attachment type | Sonder Lock |

| Liners in connections | - Rubber NBR, EPDM, FKM

- Stainless steel EN 1.4404(AISI 316L), EN 1.4301(AISI 304), SMO254,

Hastelloy C276, Titanium Gr.1

|

| Frame | - Painted frame, color RAL 5010 (other colors available on request)

- Stainless steel frame, designed for the sanitary applications (e.g.

food and dairy industries)

|

| Frame painting specification | Painting available for corrosion categories C2L, C4M, C5M

|

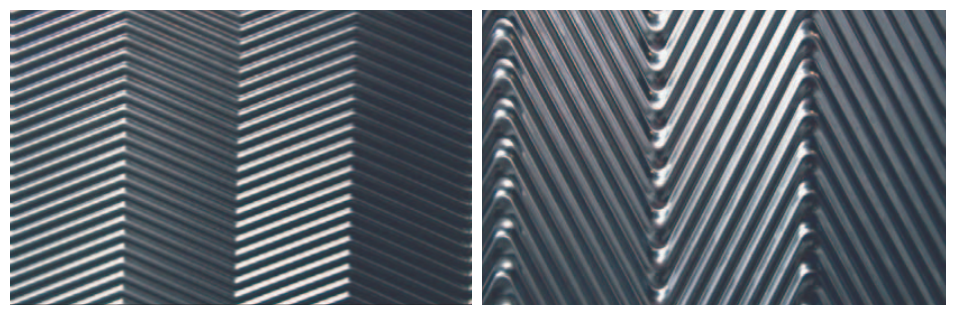

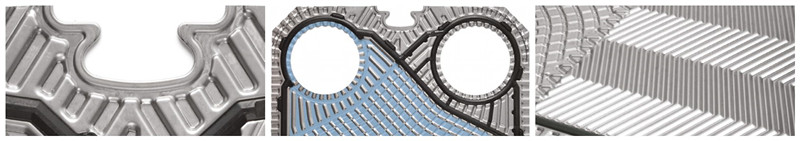

PHE Plate Feature

| FEATURE | ADVANTAGES | WHAT'S IN IT FOR YOU! |

| A | DISTRIBUTION AREA | Efficient Flow Distribution | - Prevents Mal-Distribution

|

| B | CORRUGATED PLATE PATTERN-HEAT TRANSFER AREA | Promotes Turbulence, Minimize Fouling | - Excellent heat recovery effect

- Maximize run time

|

| C | PLATE LOCKING SYSTEMS | "Corner lock" and " bubble lock" concepts ensure a stable and well

aligned plate pack when the unit is closed | - Safe and economic operation

- High serviceability

- Minimum service downtime

|

| D | EASYCLIP GASKET SYSTEM | Bevelled gasket edges easily clip into place using your flingers Stays securely in place and provides high sealing integrity | - Reliable operation

- Easy and quick to replace

- No special tools needed

|

PHE Gasket Type

Please check their are three common model gasket type are aways

used in Sondex brand.

PHE Plate Type

"Start plate with gasket""Left hand flow plate with gasket""Right

hand flow plate with gasket" End plate with gasket"

Thermal Long Plate Thermal Short Plate

- Hanging System: Plates feature a reinforced hanging system. The hanging system

helps the plates withstand the powerful tightening force, and

prevents misalignment and corner collapses. This makes plates a

solid investment, as the lifetime of the plates is increased and

service duration is reduced.

- Distribution area: The distribution area on plates is designed to prevent stagnant

zones, and ensures an even distribution of the media across the

entire plate. Furthermore, the pressure drop in the distribution

area is minimal and used on the heat transmission area instead,

which results in better heat transmission efficiency.

- Heat transmission area: With a maximized heat transmission area, we are able to reduce the

total number of plates needed for optimal performance. Our plate

patterns are fine-tuned for each application and provide the best

possible conditions for heat transfer.M&C solutions let you

dial up your efficiency and dial down your energy consumption.

M&C Plate Heat Exchanger Service and Maintenance

We can help you avoid problems before they arise with a customized

program, ranging from full maintenance support to ad hoc servicing.

We will work out the most suitable schedule with you to carry out

performance diagnostics, plate cheaning and inspections, fault

checking with quick replacements, and repairs as required.

Our skilled technicians will swiftly dismantle your heat exchangers

and expertly clean each plate using economic, environmentally -

friendly methods. We will have your installation up and running at

full capacity again in no time. We are fully equipped to perform

CIP(Cleaning in Place) where possible.

If your plate heat exchanger is faulty or under-performing, our

repair services will restore your installation to working order in

an instant. We substitute defective or worn gaskets, as well as

damaged or leaking plates, with originals or high-quality

replacements that perfectly match the specifications of your

installation.

We can also analyze your current setup to determine if the

installation can be optimized, for example by increasing the number

of plates in the heat exchanger. This is an upgrade for your entire

system, as more efficient heat exchangers improve the overall

performance while lowering the energy costs.

Whatever your needs, our dedicated service teams are standing by to

help.

Quality Control

Our quality control inspectors meticulously examine the plates for

defects. We conduct dye tests to discover potential leaks in the

plates, and perform gas tests for ammonia based plate heat

exchangers.

Every plate must meet our strict quality demands before being

shipped to our customers, to ensure a durable solution with a long

lifetime.

We are able to perform diagnostics on-site. If we uncover leaking

plates in your current installation, we can replace them with

high-performance plates that increase the relability and efficiency

of your system.

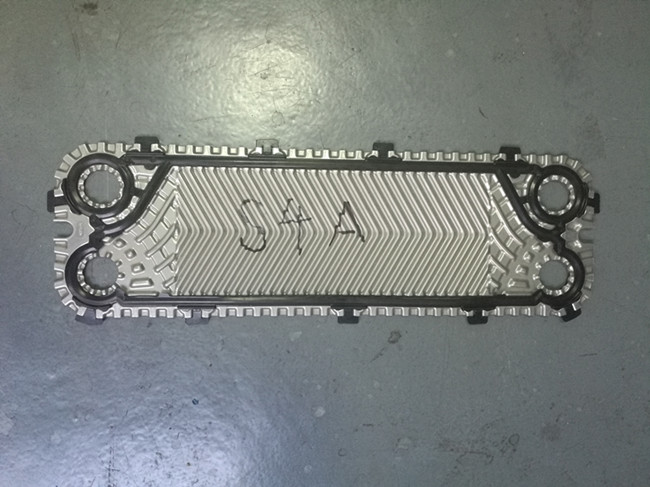

Plate Heat Exchanger Pictures

M&C Heat Parts Company Profile

M&C Heat Parts Co., Ltd is founded in Wuxi, Jiangsu. M&C is

specialized in designing and manufacturing high quality heat

transfer equipment. The range of products comprises plates &

gaskets, plate heat exchangers, gasketed heat exchangers and brazed

heat exchangers. Thus, as one of the few producers worldwide,

M&C offers solutions with optimum thermodynamic designs for

different industries and virtually all applications.

M&C provide you with one-stop accessories service,

multuple-brand & multiple model alternatives for your choice. We'll

meet all your requirements of plate heat exchanger and keep your

machine running contunously through our rich storage and quick

response.

Moreover, we have a strict quality control and after-sales service

system, from material purchasing to finished product package until

the product received in good condition. Our products have been

widely used all over the world in various fields.

M&C Plate Heat Exchanger Plates & Gaskets Other Models

Recommend

Sondex/Danfoss - S4A, S7, S20, S21, S22, S41, S43, S47, S65, S81,

S86, S100, S120, S130, SFD7, SFD13, SW19 and so on;

APV/SPX - H17, N25, N35, A055, A085, J060, J092, J107, M92, M107,

K55, K71, B110, B134, P105, P190, SR1, SR2, TR9GN, TR9AL and so on;

Tranter/Swep - GX12, GL13, GC26, GC51, GX26, GX51, GX42, GX64,

GX85, GX91, GX140, GX145 and so on;

API/Schmidt - Sigma 7, Sigma 9, Sigma 13, Sigma 26, Sigma 27, Sigma

36, Sigma 66, Sigma 106, Sigma 229, Sigma Star 45, Sigma Star 90

and so on;

Vicarb - V4, V13, V20, V28, V45, V60, V100, V110, V130 and so on;

Hisaka - EX11, EX15, EX15, LX026, LX195, LX395, LX595, RX135,

RX395, RX595, UX115, UX225, UX395, UX495, UX815, UX995 and so on;

GEA - VT04, VT10, VT20, VT40, VT80, VT405, VT805, VT1306, NT50M,

NT50X, NT100S, NT150S, NT150L, NT250M, NT250L and so on;

Funke - FP04, FP05, FP14, FP16, FP08, FP22, FP31, FP40, FP41, FP70,

FP100, FP120 and so on;

Thermowave - TL200SS/PP, TL250SS/PP, TL400SS/PP. TL650SS/PP and so

on;

DHP - DX143, DX146, DX20V, DX20DL, DX20DM, DX30S, DX36M and so on;

LHE - HT101, HT102, HT104, HT151, HT152, HT202, HT232, HT233 and so

on;

M&C Plate Heat Exchanger Goods ready to Delivery